Ceramic matrix composite (CMCs)

CMC is a breakthrough class of materials featuring high temperature oxidation stability in comparison to metals and enhanced toughness relative to monolithic ceramics. Petroceramics has developed innovative and cost-effective manufacturing methods and a unique infiltration process providing high-performing materials that survive at severe environmental conditions. We can manufacture different components with thick sections and complicated preform geometries and controllable matrix compositions such as Si, SiC, ZrC, TiC, TiB2 and B4C and mixed carbides.

Joining between CMCs with different fiber architectures

CCMs are widely used in the field of disc brakes. Among the CCMs, “CCMR” discs are high performance composites that can be obtained from carbon fiber plies which are cut and superimposed following the shape of the final product (i.e. discs). After shaping carbon vapor infiltration is performed in order to increase the density and rigidity of the preform which then undergoes machining and, in the end, liquid silicon infiltration.

Such a sequence of processes allows to obtain high performance discs for luxury cars. On the other hand cost-effectiveness is not guaranteed and, in order to overcome this issue without affecting the performance and quality of the composite based discs, Petroceramics has designed and patented a cutting edge architecture which is referred to as CCW.

In the CCW almost 50 vol % of the CCMR is replaced with a much cheaper CMC material, being obtained from a mix of chopped carbon fibers and a thermosetting resin.

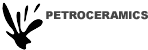

Theoretical (left) and actual (right) sandwich structure of a CCW

In the CCW processing, a sandwich structure is obtained consisting of two CCMR preform halves being molded together with an interposed chopped fiber mix. This technique turns in a reduction of the costs for the material and processes with no waste of expensive scraps.

The co-molded materials undergo liquid silicon infiltration which allows a very effective in-situ joining of the three components of this sandwich architectures.

Polymer Impregnation and Pyrolysis (PIP) process

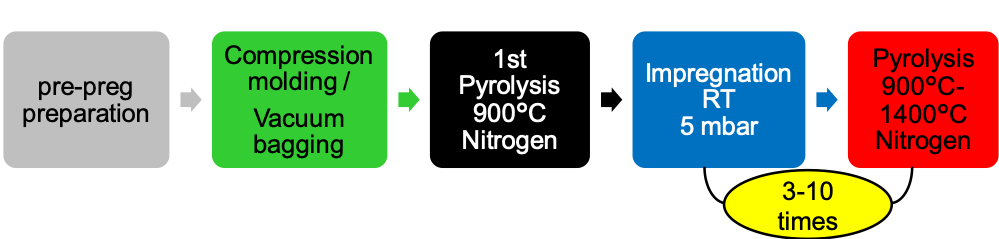

Petroceramics developed a cost effective process for the manufacturing of CMCs by means of the PIP process. The process steps are summarized here below.

Summary of the steps involved in a standard PIP process

Summary of the steps involved in a standard PIP process

A first pyrolysis treatment is performed after shaping the green parts, in order to partially decompose the polymer and to obtain a porous preform.

The preform density is then progressively increased (and the residual porosity decreased) by means of several (3 to 10) alternations of impregnation and pyrolysis steps. Impregnations are performed at room temperature in vacuum and a pre-ceramic resin is used. After each impregnation step a pyrolysis treatment is performed in order to convert the resin into a ceramic matrix.

This material can withstand operating temperature up to 800°C for short duration exposure. Large scale productions and cost effectiveness can be achieved with this process which led Petroceramics to consider the application of this material for the manufacturing of brake discs.