One of our most remarkable expertise is the ability to adapt the architecture of materials to the finale application requirements.

The overall orientation (direction and the distribution) of the reinforcing elements (i.e. carbon fibers, CFs) controls two very important properties of a fiber reinforced composites, that are the thermal conductivity and the mechanical strength.

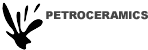

A standard industrial process leading to high performances carbon preform (to convert to carbon fiber reinforced carbon matrix composites – CFCs - or to CMCs) starts from (continuous) carbon fiber plies which are cut and superimposed following the shape of the final product (i.e. discs).

Standard industrial process for carbon preforms manufacturing

In this way all the carbon fibers in the preform are oriented in-plane thus optimizing the in-plane heat dissipation which is likely for braking disc applications. Despite good in-plane thermal dissipation is guaranteed, low and non-uniform mechanical strength is commonly achieved.

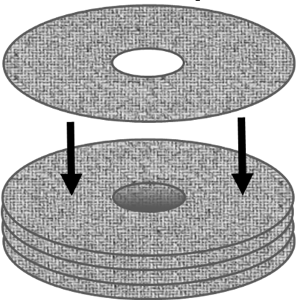

Petroceramics developed a novel approach to shape a coiled carbon preform with a fine control over the distribution of the reinforcing fibers. The technology permits to arrange most of the fibers (both chopped or continuous fibers and woven or non-woven plies) in a plane which is tangential with respect to curved surface of the coiled disc. Such a structure maximizes the thermal conductivity in the axial direction and also enhances the mechanical strength.

Sheet winding forming technology (left) and a CMC wound component (right)